- Home

- »

- Board Book Printing

Custom Board Book Printing for Babies: Safe, Durable & Certified

Looking for a printing partner who understands that babies chew on books?

We specialize in manufacturing indestructible board books that withstand toddlers’ wear and tear. Unlike standard printers, we use 100% non-toxic soy inks, food-grade lamination, and safety rounded corners as our default standard.

Whether you are a self-publisher or a publishing house, we ensure your books are CPSIA (USA) and EN-71 (Europe) certified, making global export 100% hassle-free.

- CPSIA & EN-71 Compliant

- Non-Toxic Inks & Materials

- Durable, Chew-Proof Construction

Board Book Solutions & Features

We offer a comprehensive range of board book styles and interactive features. Explore our capabilities to find the perfect format for your project.

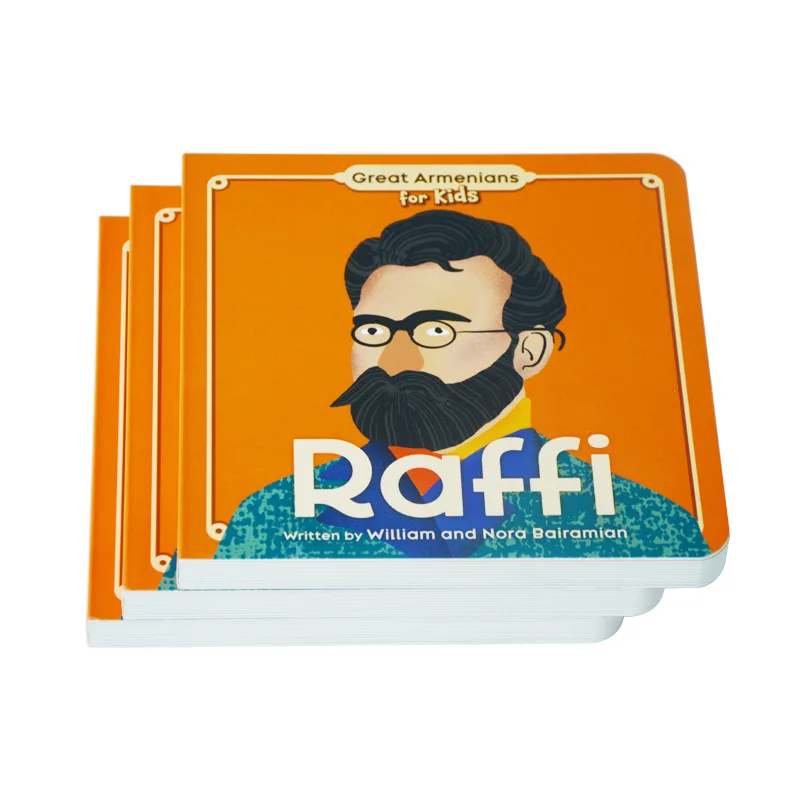

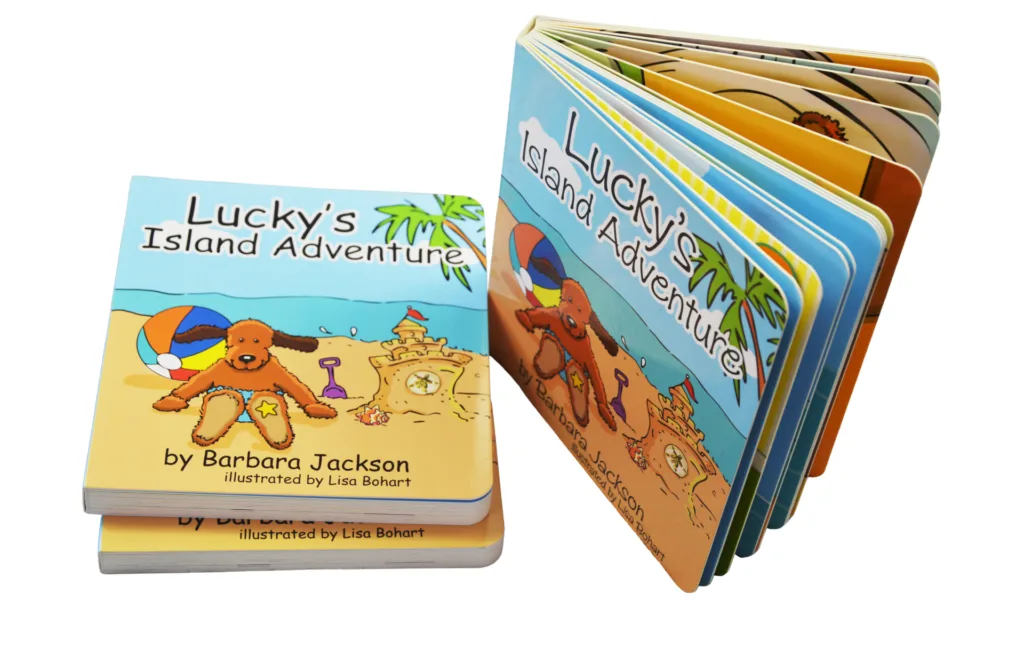

Self-Cover Board Book Printing

A seamless and modern design where the cover and pages share the same durable board. This cost-effective style is perfect for high-volume orders, promotional items, and sturdy storybooks.

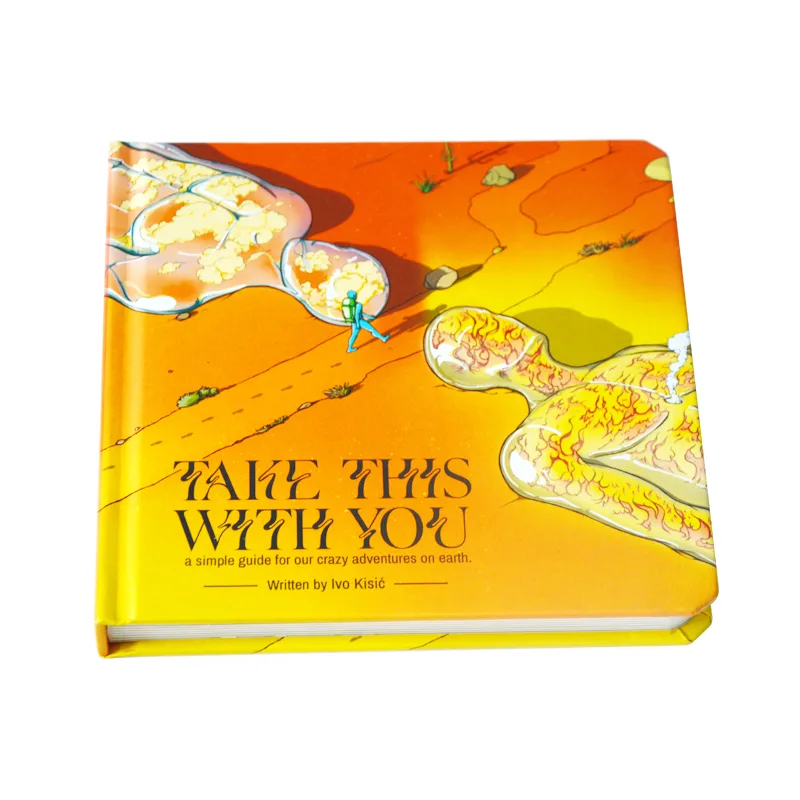

Hardcover Board Book Printing

Combines ultra-durable board pages with the elegance of a classic, case-wrapped hardcover. This premium style provides superior protection and expanded finishing options, creating a true keepsake book.

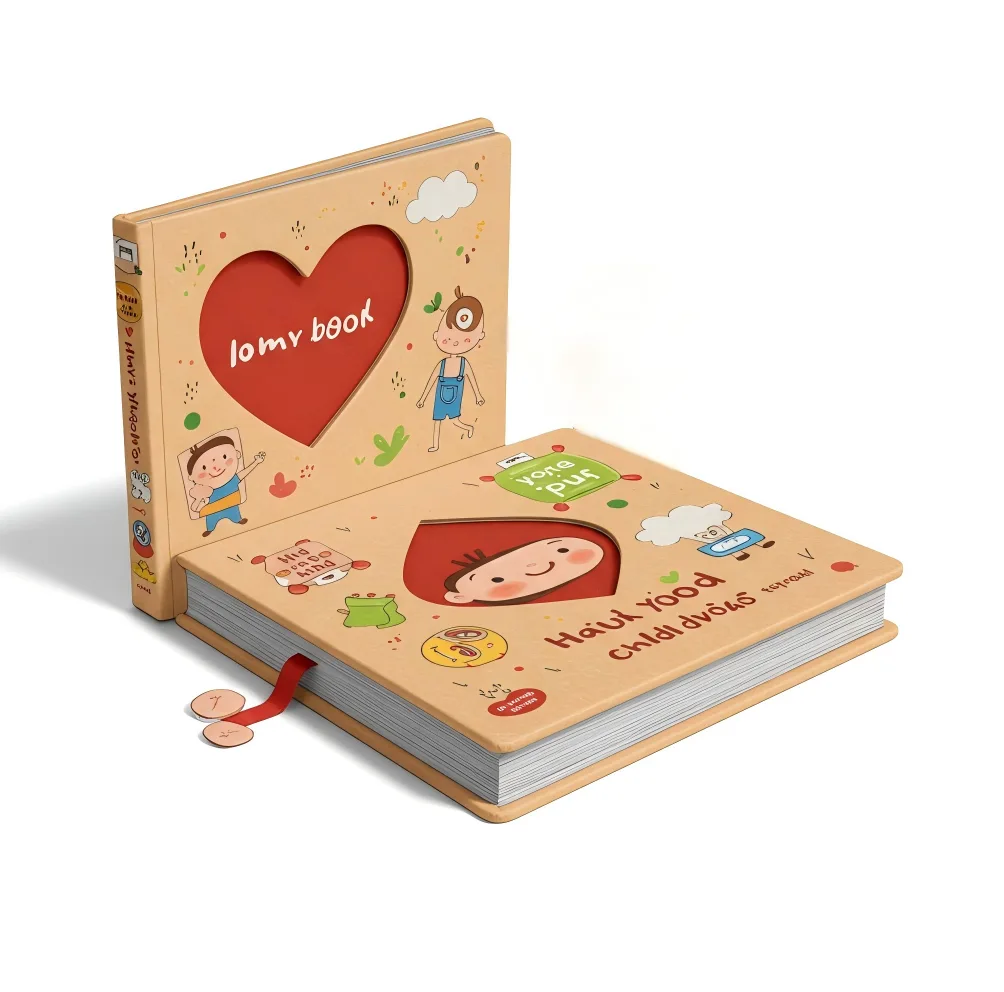

Interactive Board Book Printing

Boost engagement with expertly integrated sensory features. We manufacture a wide range of robust interactive elements, including:

Lift-the-Flaps

Touch-and-Feel Textures

Pull-Tabs & Sliders

Velcro & Magnetic Elements

Custom Shaped Board Book Printing

Capture attention by die-cutting your book into any unique shape, from a character to an animal or object. This format offers maximum shelf appeal, turning your story into a memorable, interactive toy.

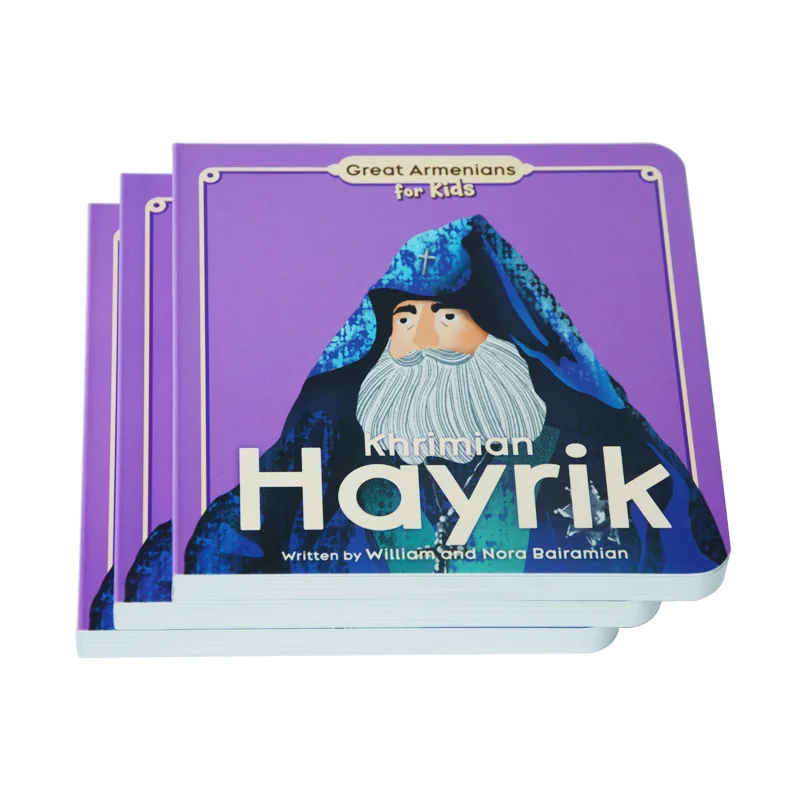

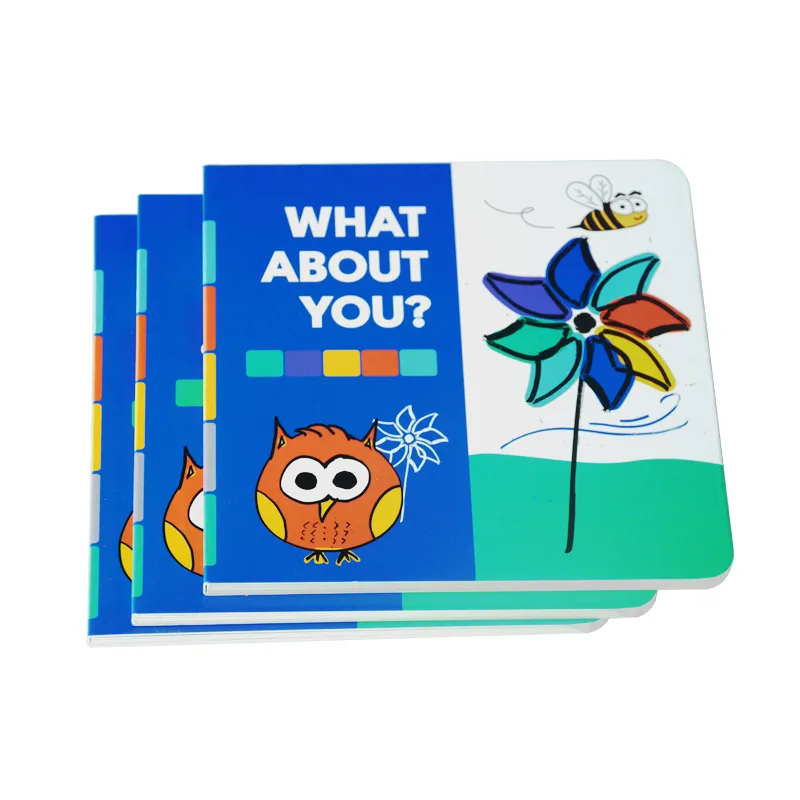

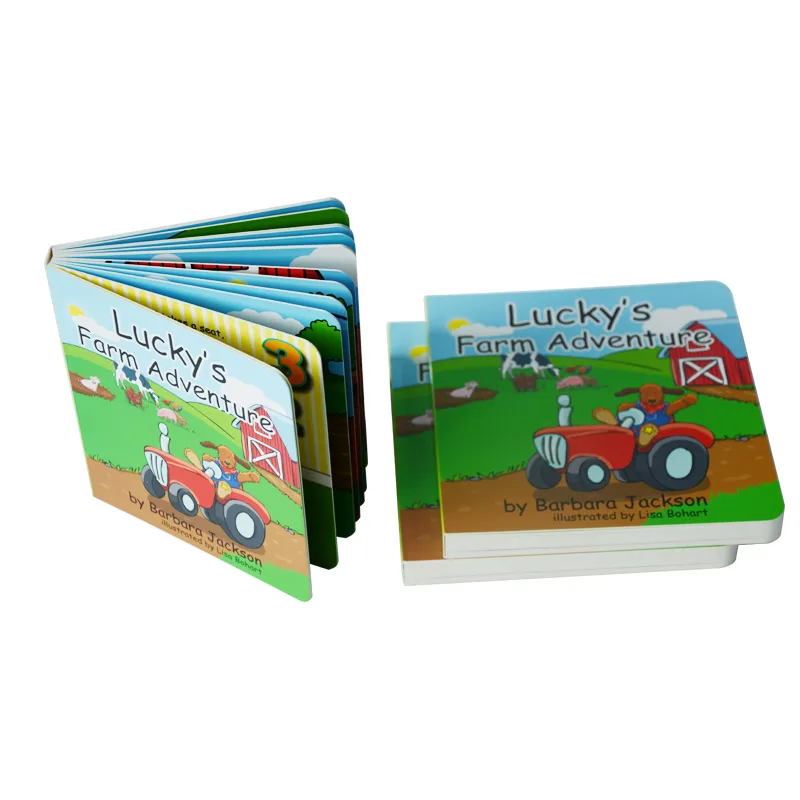

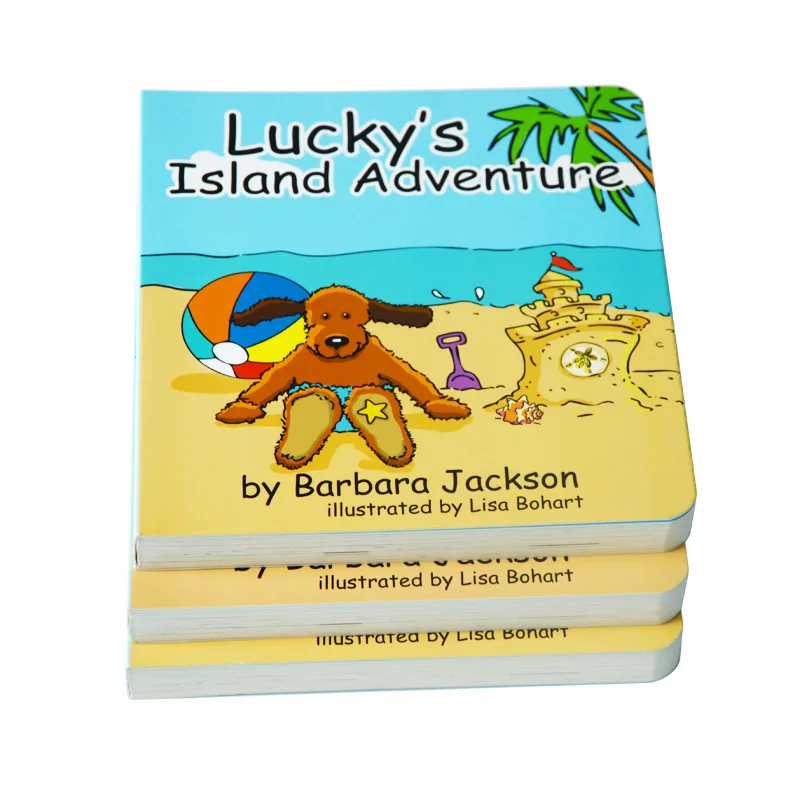

A Showcase of Our Custom Board Books

See how we’ve helped publishers, authors, and brands create safe, durable, and engaging custom board books for the world’s youngest readers.

Building Your Perfect Board Book

Choosing the Right Size for Your Board Book

The size of your board book is a crucial first step. It determines how easily a child can hold it, impacts the visual space for your art, and is a key driver of the final production cost. For a detailed analysis of how size, materials, and other factors influence your budget, please see our complete guide to board book costs.

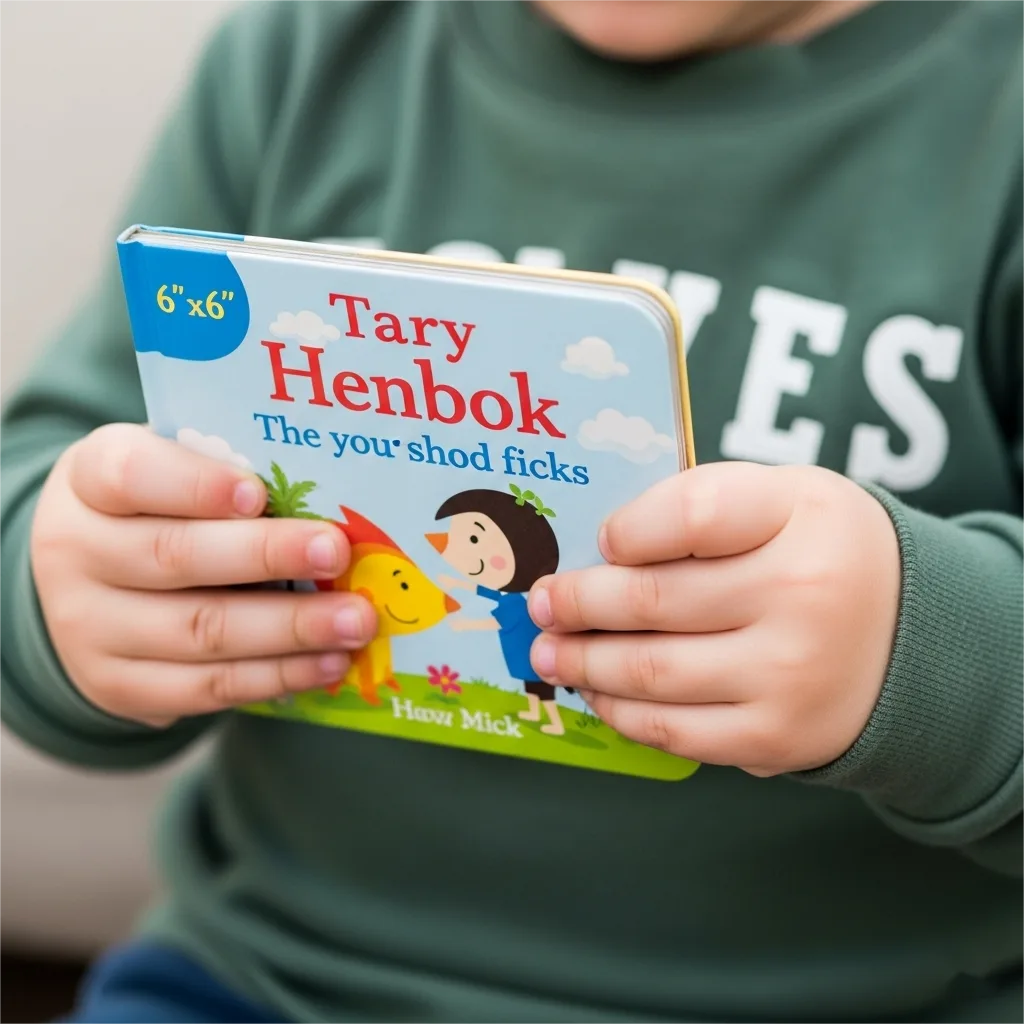

Classic Square Formats

These are the most popular choices for their cost-effectiveness and ease of use for little hands.

Our most popular standard dimensions include:

5.5″ x 5.5″ (140 x 140 mm): The perfect starter size for babies (0-1 years).

6″ x 6″ (152 x 152 mm): A versatile and classic format for toddlers.

7″ x 7″ (176 x 176 mm): Offers more generous space for detailed illustrations.

Custom & Die-Cut Shapes

Go beyond the square to create a book that is also a toy. A unique shape makes your product stand out dramatically on any shelf.

We specialize in die-cutting board books into imaginative shapes. For example, we can create books shaped like:

An animal

A vehicle (like a truck or train)

A beloved character

These uniquely shaped pages function like durable, individual cards. To keep the set organized and easy for little hands to manage, we typically bind them with a single, child-safe ring—making this format perfect for flashcards or on-the-go learning.

Our team can provide dieline templates for these standard sizes or help you develop a fully custom shape for your project.

Understanding Board Book Page Count

Counting pages for a board book is unique, and getting it right is essential for your project plan. Total pages (including front and back covers) MUST be divisible by 2, ideally between 8 and 32 pages.

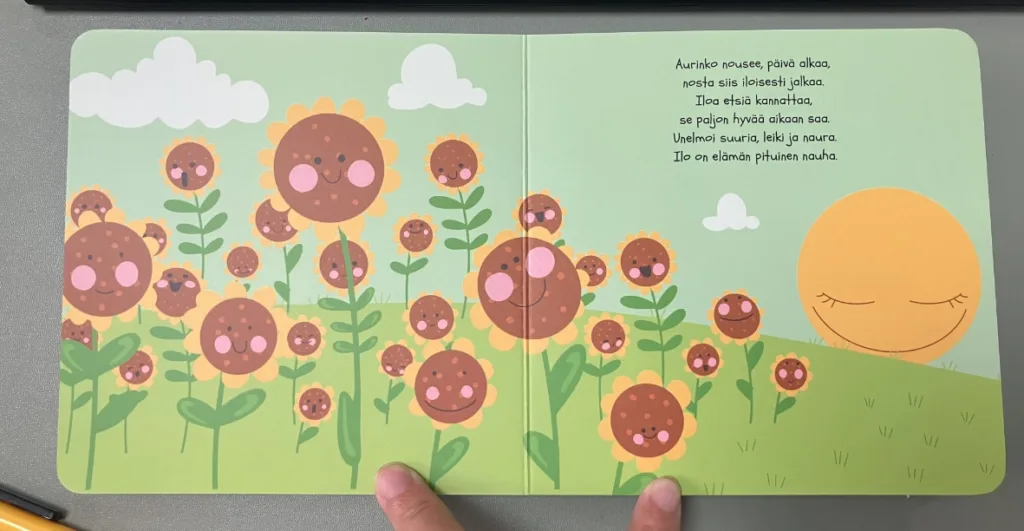

The Power of a "Spread"

The most important concept for your book’s design is the “spread.”

A spread refers to the two facing pages you see when the book is laid open—a left-hand page and a right-hand page. Designers often treat this as one continuous canvas. This is perfect for large, panoramic illustrations that flow seamlessly across the book, creating a more immersive experience for young readers.

Understanding this is key to planning your book’s layout. For example, a 12-page board book is typically understood in the printing industry as having:

5 Interior Spreads (which equals 10 pages, as 1 spread = 2 pages)

1 Front & Back Cover

We’ll help you confirm your final page count and provide the correct templates to ensure your artwork fits perfectly.

Board Book Construction: Paper & Thickness Options

The signature sturdiness of a board book comes from its unique construction. Unlike regular books, the pages are engineered by mounting multiple layers of high-quality paperboard together. This process allows us to customize the thickness and rigidity of each page to create the perfect feel and durability for your project.

We primarily use C1S (Coated One Side) paperboard. The smooth, coated side is perfect for vibrant, crisp printing of your illustrations, while the uncoated side provides an excellent surface for the strong, non-toxic adhesive that bonds the layers together.

Below are some of our popular construction options. The choice often depends on the target age group and the desired premium feel of the book.

Expert Guide: Sizes & Materials

1. Popular Standard Sizes (Cost-Effective): While we support any custom shape, sticking to standard molds saves you money:

6″ x 6″ (152mm): The classic square format. Perfect for little hands.

5″ x 7″ (127x178mm): Portrait format, great for storytelling.

2. Core Selection: Greyboard vs. Whiteboard

Greyboard (The Industry Standard): 350gsm C1S paper mounted on a grey core. Pros: Durable, lower cost, eco-friendly look. Best for: Mass-market runs.

Whiteboard (The Premium Choice): Solid white layers through and through. Pros: Pristine white edges, cleaner look. Best for: High-end gift sets or luxury editions.

Board Thickness Specifications

Construction | Resulting Thickness | Best For |

350gsm C1S + 350gsm C1S | 1.0 mm | Standard & Most Popular. A perfect balance of durability and value. Ideal for toddlers (1-3 years) and general use. |

400gsm C1S + 400gsm C1S | 1.1 mm | For a noticeably more premium and rigid feel. An excellent upgrade for high-quality storybooks or keepsake editions. |

Three Layers: 250g C1S + 350g C1S + 250g C1S | 1.2 mm | Increased thickness and strength. A great option for books with simple interactive elements or for a younger age group. |

Three Layers: 250g C1S + 400g C1S + 250g C1S | 1.3 mm | Very durable and stiff. Recommended for books intended for heavy handling or for adding extra perceived value. |

Three Layers: 350g C1S + 350g C1S + 350g C1S | 1.4 mm | Ultra-durable and virtually indestructible. Best for babies (0-2 years) and complex interactive books (e.g., sound modules). |

Our Quoting Standard

Please note: To provide the best balance of high quality and competitive pricing, our standard quotes are based on the 350gsm + 350gsm construction, resulting in a ~1.0 mm page thickness. If you require a different thickness, please specify this in your quote request.

Have a Specific Requirement?

The options above are not exhaustive. We are a custom manufacturer and can source different material weights or create unique multi-layer constructions to achieve your desired thickness and rigidity. Partner with us to engineer the perfect board book for your vision.

Finishes & Special Features

Finishing is the critical step that adds durability, safety, and a “wow” factor to your board book.

While all of our board book pages are laminated by default (in your choice of gloss or matte) for essential protection, you can choose from the following special features to make your book truly unique.

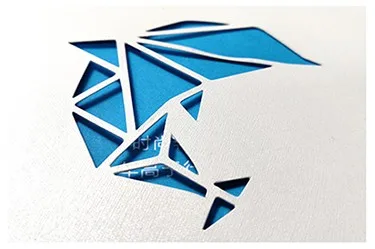

Die-Cutting (Custom Shapes & Windows)

With precision die-cutting, we create books in any custom shape (like an animal or vehicle) or add "peek-a-boo" windows to pages. This sparks curiosity and makes your book unique.

Foil Stamping

Apply metallic foil for an elegant, eye-catching effect. It's perfect for highlighting titles, logos, or creating magical, shimmering details that add a premium touch.

Touch-and-Feel Textures

Engage a child's sense of touch by applying various child-safe textures to illustrations, such as soft flocking (for fur), gritty surfaces, or smooth, glossy patches.

Spot UV & Glitter

Create captivating visual effects. Spot UV adds a localized gloss or raised texture to specific areas, while glitter provides a safe, eye-catching sparkle to make elements pop.

The features above are our most popular, but we are not limited to them. Our expert team can advise on these options and is ready to discuss developing any unique finish you have in mind.

Have a unique idea?

We partner with clients to develop innovative and custom board book solutions beyond this list. Inquire to discuss your vision.

Why Choose Mainland Printing?

From dedicated support to transparent pricing, we provide a seamless manufacturing experience built on expertise and trust.

Your dedicated project manager is an expert in board book specifics, providing clear, proactive guidance at every step of the process.

As a direct manufacturer, we provide detailed quotes with no hidden costs. We help you find the most cost-effective solution for your bulk order.

We specialize in the precise manufacturing of engaging features, from unique die-cuts and sturdy lift-the-flaps to various touch-and-feel elements.

We simplify your setup process with specialized dieline templates and a free file check. For a complete walkthrough, explore our in-depth file preparation guide to ensure your artwork is perfect.

Feel the quality for yourself. We highly recommend a pre-production sample to verify board thickness, color vibrancy, and durability before the full run.

We ship bulk orders worldwide with robust, secure packaging, full tracking, and customs support to ensure your books arrive in pristine condition.

Our Commitment to Safety, Durability & Quality

For children’s board books, every detail matters. We combine an uncompromising commitment to international safety standards with a robust manufacturing process, giving publishers and authors complete confidence in a beautiful, durable, and safe final product.

Built for Durability & Safety

Our expert process mounts printed sheets onto thick, multi-layered paperboard, creating an incredibly sturdy book that resists bending, tearing, and chewing.

Child-Safe Adhesives: Layers are bonded with certified low-odor, non-toxic glues for structural integrity and child safety.

Protective Lamination: Every page is sealed with a child-safe protective film, making the entire book wipeable and tear-resistant.

Standard Rounded Corners: Features precisely rounded corners to prevent pokes and cuts, ensuring the book is completely safe for little hands.

Certified & Eco-Friendly Materials

We exclusively use materials proven to be safe for children and compliant with major international regulations like CPSIA (U.S.) and EN-71 (Europe).

Non-Toxic, Soy-Based Inks: Your illustrations are printed with vibrant, eco-friendly inks that are free from harmful VOCs and heavy metals.

FSC-Certified Paper: We offer paper and board stock sourced from responsibly managed forests to support global sustainability.

Contact us to get the safety reports.

Need official certification for your specific project? We can assist in getting your finished book tested here in China by accredited third-party labs.

Rated "Excellent" on Trustpilot

Hear directly from global clients on Trustpilot – learn about their real-world experiences with our book printing services.

Rated 4.7 / 5 based on 26 reviews. Showing our latest reviews.

Case Studies & Insights

Beyond the CPC Certificate: Our 5-Step Heavy Metal Screening Process for Toddler Board Books

Worried your current printing production won’t pass a strict US safety audit?…

How Much Does It Cost to Print a Board Book? The Complete 2026 Breakdown

Stop guessing on your next board book project. This guide moves beyond…

What is a Hardcover Book? A Guide for Publishing Pros

Want to create hardcover books that readers will treasure? This comprehensive guide…

Have a Question?

FAQ

Here are answers to some common questions about custom board book printing. If you don’t see your question here, please don’t hesitate to contact our expert team for more details.

What is the difference between 40pt and 60pt board book thickness?

The “pt” or “point” refers to the paperboard’s thickness. In simple terms, a 60pt board is significantly thicker and more rigid than a 40pt board.

- 40pt Board (approx. 1mm thick per page): This is the industry standard for most high-quality board books. It provides excellent durability for toddlers, offering a sturdy feel while still being relatively easy for small hands to turn the pages. It’s a great balance of quality and cost-effectiveness for bulk orders.

- 60pt Board (approx. 1.5mm thick per page): This is a premium, extra-durable option. The increased thickness and rigidity make the book feel more substantial and virtually indestructible, perfect for books targeting very young babies (0-2 years) or for high-end keepsake editions.

We can provide samples of both to help you feel the difference.

Are your board books safe for teething babies?

Yes, absolutely. The safety of teething babies is a primary consideration in our manufacturing process. We ensure this through several key measures:

- Non-Toxic Materials: We exclusively use certified child-safe, non-toxic soy-based inks and low-VOC adhesives.

- Physical Safety: All our board books are produced with smooth, rounded corners as a standard feature to prevent pokes and cuts.

- Durable Construction: The multi-layered, laminated pages are highly resistant to tearing and chewing, minimizing the risk of small pieces breaking off.

- Compliance: We have deep expertise in meeting international safety standards like CPSIA and EN-71, and can assist with third-party testing to certify your final product.

What is the minimum order for custom board books?

Custom board books require a specialized “Mounting” process (gluing cardboard layers together). This requires industrial setup on offset printing machines.

Printing fewer than 300 copies is possible but results in a high unit cost. Bulk printing is the most cost-effective choice.

What is the typical turnaround time for a board book project?

A typical board book project timeline is broken into three phases:

- Sampling: 5-10 business days after file confirmation.

- Mass Production: 15-35 business days, depending on the order quantity and the complexity of any interactive features.

- Shipping: Varies by destination and method (e.g., 30-40 days to the US/Europe by sea).

We will provide a detailed, project-specific schedule with your formal quotation.

What information do you need for an accurate board book quote?

To provide you with the most accurate quote, please provide the following specifications:

- Book Dimensions (Height x Width)

- Page Count (e.g., 16 pages, including cover and back)

- Desired Board Thickness (e.g., 40pt)

- Quantity (e.g., 500, 1000, 2000+)

- Finishing Details (e.g., Matte or Gloss Lamination)

- Any Special Features (e.g., Lift-the-flaps, die-cuts, Spot UV)

- Shipping Destination (Country with post code))

You can submit these details on our Request a Quote page

How do you prevent common issues like warping in board books?

This is an excellent, technical question. Warping is a common industry challenge that we mitigate through strict process control:

- Climate-Controlled Environment: Our workshop maintains stable temperature and humidity to minimize environmental effects on the paperboard.

- Material Acclimatization: We allow the board stock to acclimate properly before production begins.

- Balanced Construction: We ensure the paper grain direction is consistent and that lamination is applied evenly to balance tension, which is a key factor in preventing warping.

- Proper Curing Time: After gluing and mounting, the books are placed under pressure and allowed to cure for an adequate period to ensure a strong, stable, and flat final product.

Ready to Create a Durable & Engaging Board Book?

Let Mainland Printing be your expert partner in board book manufacturing. We specialize in creating sturdy, engaging books for babies and toddlers, focusing on child-safe materials, warp-resistant construction, and vibrant printing.

We offer expert guidance, volume pricing, and reliable global delivery to turn your vision into a treasured first book.

Get Your Factory-Direct Quote

Response within 12 hours. Save up to 40% on bulk orders.

🔒 100% Privacy. No Hidden Costs. Free Sample Options.