Your order quantity is key when choosing book printing technology, a decision crucial for managing your costs and risks effectively. This guide helps you clearly select between Offset, Digital, and Print-on-Demand (POD) to make the most cost-effective choice for your print run.

Order quantity dictates printing technology: use Print-on-Demand (POD) for 1-100 copies (zero risk, higher unit cost), Digital printing for 100-1500 (fast, flexible, good value), and Offset printing for 1500+ (lowest unit cost at scale, requires high volume). Always factor total cost and timeline into your decision.

In essence, matching your order quantity to the right printing technology (POD, Digital, or Offset) is key, but also weigh total costs and associated risk factors. Read on for detailed quantity breakdowns, essential cost considerations, and strategies to choose wisely for your book.

The Fundamental Principle: How Order Quantity Dictates Printing Costs

You might wonder why the number of books you plan to print plays such a massive role in choosing the right book printing technology. It all boils down to how printing costs are structured. Understanding two key concepts – fixed vs. variable costs and economies of scale – makes this much clearer.

Fixed Costs vs. Variable Costs Explained

Think of fixed costs as the initial setup expenses for a print run. These costs generally stay the same whether you print 100 books or 10,000 books. For traditional offset printing, this includes creating the printing plates (which can cost around $300-$500 or more depending on the job) and the “make-ready” process to prepare the press. Digital printing, on the other hand, has very low or even zero fixed setup costs because it doesn’t require plates.

Variable costs, however, are tied directly to each book printed. These include the ink or toner, the paper, and the binding materials used for every single copy. The more books you print, the higher your total variable costs will be.

Here’s the key takeaway: Offset printing has high fixed costs but lower variable costs per book once the press is running, a key point when considering Offset vs Digital Printing. Digital and POD have low fixed costs but relatively higher variable costs per book. This fundamental difference is why large order quantity favors offset, while smaller orders are better suited for digital or POD.

Understanding Unit Cost & Economies of Scale

The unit cost is simply the total cost of your print job divided by the number of books printed (Total Cost / Quantity = Unit Cost). Your goal is usually to get the lowest possible unit cost while meeting your quality and timeline needs.

This is where economies of scale come in, particularly for offset printing. Because those high fixed setup costs are spread across all the books printed, the more books you print, the less each individual book has to “contribute” to covering those setup costs. This means your unit cost drops significantly as your order quantity increases with offset printing. Printing 2,000 books via offset will almost certainly give you a much better unit price than printing just 500.

Digital printing and POD benefit much less from economies of scale. Since the setup cost is minimal, the cost to print the 500th book isn’t drastically different from the cost to print the 10th book. While there might be slight price breaks for larger digital orders, the unit cost remains relatively stable compared to the sharp decrease seen with offset.

Decoding the Main Printing Technologies: Offset vs. Digital vs. POD.

Table Title: Comparison of Book Printing Technologies: Offset vs. Digital vs. POD

| Feature | Offset Printing | Digital Printing |

Print-on-Demand (POD)

|

| Best Order Quantity | 1500/2000+ copies | 100 – 1500/2000 copies | 1 – 100 copies |

| Unit Cost Trend | Decreases significantly w/ volume | Relatively stable |

Highest, relatively stable

|

| Setup Cost | High (Plates, Make-ready) | Low / None |

None (Uses Digital Printing)

|

| Turnaround Time | Slow (4-8+ weeks) | Fast (3-10 days print time) |

Fastest Print Time (1-3 days)

|

| Inventory Risk | High | Low | None |

| Ideal Use Case | Lowest unit cost at scale, bulk | Speed, Flexibility, Small/Med runs |

Zero risk, Testing, Backlist, Niche

|

| Typical Quality | Excellent / Consistent at Scale | Excellent | Good / Can Vary |

| Option Flexibility | Widest (Paper, Ink, Finish) | Good / Standard Options Available | Most Limited |

Now that you understand how costs work, let’s look closely at the three main players in the book printing world: Offset, Digital, and Print-on-Demand (POD). Each has its strengths and weaknesses, especially when considering your order quantity.

Offset Printing: The Standard for High Volume

Offset printing is the traditional workhorse of the commercial printing industry, involving a detailed process with plates and ink transfer. It involves creating metal plates of your book’s pages, which then transfer ink onto a rubber blanket, and finally onto the paper.

- Best For: Offset truly shines when you need large quantities. Generally, it becomes cost-effective around 1,000 to 1,500 copies and significantly cheaper per book when you get into runs of 2,000, 3,000, or more.

As self-publishing expert Joel Friedlander notes, while 500 books might be the lowest practical quantity for offset, you’ll likely see a “good unit price” starting around 2,000 copies. - Pros: Lowest possible unit cost at high volumes; widest range of paper/ink/finishing options; potentially highest quality consistency for large runs.

- Cons: High upfront setup costs; longer production times (typically 6-8 weeks); significant financial risk and inventory management required; printers have Minimum Order Quantities (MOQs).

Digital Printing: Flexibility for Short-to-Medium Runs

Digital printing works more like your sophisticated office printer, transferring your digital file directly onto paper without using plates. Common technologies include laser (using toner) and high-speed inkjet.

- Best For: Digital is the go-to choice for short-to-medium print runs, generally from around 100 up to 1,500 or even 2,000 books.

- Pros: Minimal setup costs; fast turnaround times (often 3-10 business days); easy reprints & updates; excellent print quality with modern equipment (often indistinguishable from offset for standard books); ideal for market testing.

- Cons: Higher unit cost than offset for large volumes; slightly more limited options than offset for some specialty papers/finishes.

Note: Even with digital, quantity affects unit cost somewhat due to handling. For example, one analysis showed a complex book cost $22.99/copy for 81 units vs. $18.24/copy for 154 units.

Print-on-Demand (POD): Ultra-Low Volume & Zero Inventory

POD isn’t a separate printing method but rather a fulfillment model that uses digital printing. Books are printed individually only after they are ordered by a customer – sometimes just one copy at a time.

- Best For: POD is perfect when you need just a handful of copies (1 to 100), want to test a book concept with absolutely minimal financial risk, or keep backlist titles available without holding stock.

- Pros: No upfront printing investment & zero inventory risk. As author Sam Jordison highlights for self-publishers, POD offers “fewer upfront costs” and “no inventory” concerns, a major advantage when evaluating Offset vs POD printing methods. Often integrates with sales platforms (like Amazon KDP/IngramSpark), simplifying distribution.

- Cons: Highest cost per book; often limited choices in paper, size, and binding; quality consistency can sometimes vary.

The Decision Framework: Matching Quantity to Technology

Choosing the right technology often comes down to the number of books you need. Here’s a breakdown by common quantity tiers:

Tier 1: Ultra-Low Volume (1-100 Books)

- Recommendation: Print-on-Demand (POD).

- Why: Minimizes financial risk, perfect for testing demand or fulfilling niche orders. While Mainland Printing focuses on B2B batch printing, services like KDP or IngramSpark handle this one-off need.

Tier 2: Small Batches (100-500 Books)

- Recommendation: Digital Printing.

- Why: Best balance of affordability, speed, and quality for planned small runs. Avoids high offset setup. Ideal for many initial print runs.

Tier 3: The Crossover Zone (500-2000 Books)

- Recommendation: Critically Compare High-Quality Digital vs. Short-Run Offset.

- Why: This is where the “cost break-even point” often lies. The best choice depends on specific quotes, timeline needs, quality priorities, and your comfort with holding inventory.

Tier 4: Large Volumes (2000+ Books)

- Recommendation: Offset Printing.

- Why: Unbeatable unit cost savings for high volumes. Standard for established demand. Crucially, remember to factor in total costs including shipping and storage when comparing.

Making this final choice always requires getting detailed, comparable quotes based on your specific book details.

Beyond Quantity: Essential Factors for Your Final Decision

While quantity is primary, briefly consider these final points:

Calculating the TRUE Cost of Ownership (Especially for Offset):

Don’t forget shipping (pallets!), warehousing, and potential waste when comparing offset quotes to digital. The “cheap” offset unit price might hide significant backend costs.

Turnaround Time Needs:

How fast do you need books? POD is fastest (1-3 days print time), then Digital (3-10 days), then Offset (4-8 weeks). Match this to your launch plans.

Quality Expectations vs. Budget:

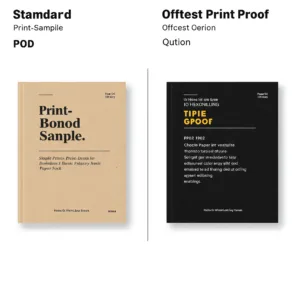

Modern digital quality is excellent for most books. Offset might be preferred only for highly specific needs (exact PMS colors, unique papers). Always ask for samples!

Risk Tolerance & Inventory Strategy:

How much financial risk can you take? How will you manage inventory?

Consider starting small with Digital/POD to test demand before determining when to switch POD to Offset Printing if your book proves successful.

Conclusion: Making the Smart Choice

Navigating the world of book printing technology becomes much clearer when you let your order quantity be your primary guide. POD offers zero-risk entry, Digital provides flexibility for small-to-medium runs, and Offset delivers cost savings at high volumes.

Always layer in considerations of the total cost, your timeline, quality needs, and risk comfort. Getting specific quotes based on your book’s details is the essential final step. Making an informed decision about your book printing technology based on your order quantity ensures you manage costs effectively and bring your book to readers efficiently.

Ready to explore the best printing option for your specific book and quantity? Contact Mainland Printing today. As a dedicated B2B book manufacturer serving the US and Europe, we offer high-quality printing and binding solutions (Hardcover, Softcover, Children’s Books, and more) and can provide a free, no-obligation quote tailored to help you choose the most cost-effective printing technology.